Processing with performance

Empowers processors to capture real-time data and turn it into actionable insights

Facilitates KPI tracking, efficiency optimization, and full product traceability

Enables management and operating staff to make smarter, data-driven decisions

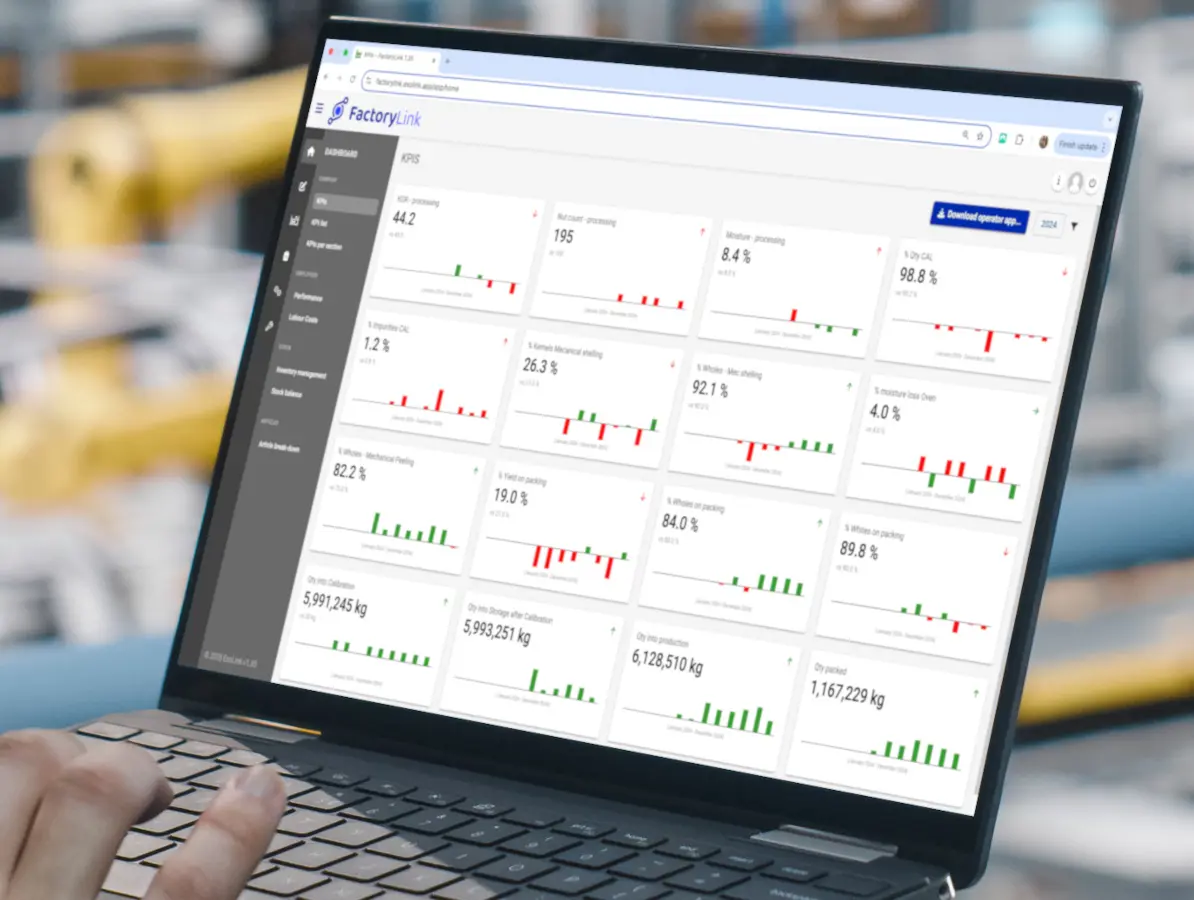

Monitoring of production KPIs

Performance monitoring on targets and actuals, with customized KPI settings, displayed in one overview dashboard.

Discover more

Define & connect

Configuration of the factory flow, key metrics and scales for automatic weighingRegistration

Registration of weights, quality parameters through the stand-alone operator appKPI monitoring

KPI configuration and real time monitoringProduction reports

Production reports on all production factors and performance over periods, including benchmarking and forecast targetsEmployee performance

Track individual labor performance, and weights, with integrated gross salary calculations.

Discover more

Human resources

Registration and organization of all workers, including diversified tarifficationRegistration

Registration of individual weights through the stand-alone operator appPerformance monitoring

Monitoring of labor productivity, attendance per employeeSalary payments

Gross salary per employee, including allowances and salary payroll summaries and benchmarking with living wage

Inventory policy

Configuration of inventory products, sections and intervals, including alertsVerification

Check of number of packaging and weights through the stand-alone Operator appBalance

Opening and closing stock balance real-time and for any historical periodStock management

Stock position and managing orders according to production dates

Traceability policy

Configuration of production flow and standardized lot managementLot tracing

Identify lot codes and labels with QR codes, linked with own referencesDue diligence

Product traceability as the backbone of Due Diligence for standards and certificationsReports

Lot tracking through the process, including the breakdown of KPIsMaintenance monitoring

Optimize spare part use and maintenance intervention with proactive maintenance to minimize downtime.

Discover more

Planning

Plan preventive and routine maintenance activities to ensure smooth operationsTrack spare parts

Consumption of spare parts and supplies, including critical stockLog repairs

Record completed repairs, replacements, and upgrades to maintain a clear maintenance historyAnalyze & optimize

Use reports and insights to improve maintenance schedules and reduce downtime